During the epidemic, we will make full efforts and step up testing to ensure the quality of steel structure products

time2020/08/03

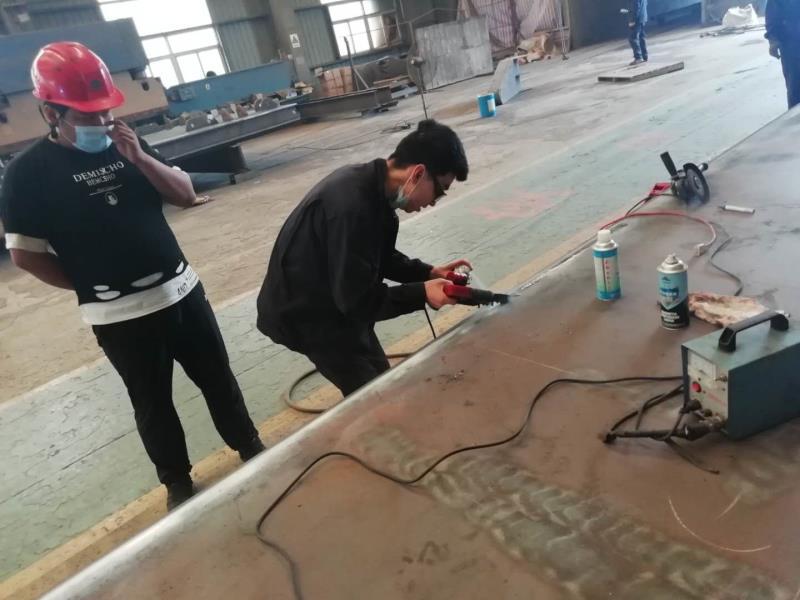

- Recently, our company’s factory technical engineers conduct welding process qualification tests on steel structure products, and conduct flaw detection tests on product welds. This quality inspection is carried out in strict accordance with relevant standards and regulations. The company’s technical staff carefully wrote on-site inspection records.

Recently, our company’s factory technical engineers conducted welding procedure qualification tests on steel structure products, and conducted flaw detection on the welds of the products. They not only checked the surface of the products for defects, but also assessed the capabilities of the company’s technical staff. This quality inspection was carried out in strict accordance with relevant standards and regulations, and the company’s technical staff carefully wrote on-site inspection records.

The steel structure products produced by our company are made of high-quality Q355 material. According to the different construction scales, customers can customize the specifications and models they want. The welding system of the products is in accordance with the EN1090 certification standard. The steel surface is sandblasted and derusted. Wait for treatment and the product has been preservative.

This quality inspection uses a magnetic flaw detection method to detect the welds of steel structure products. It is a method of using ferromagnetic materials to change the magnetic rate due to defects on the surface and near the surface. When magnetizing, a leakage magnetic field is generated on the surface, and magnetic powder, A method of recording and displaying defects with magnetic tape or other magnetic field measurement methods. This method not only has high sensitivity and fast speed, but also can detect defects at a certain depth on the surface. The test results show that the steel structure product meets the requirements of welding process standards and acceptance specifications, and no surface defects such as pores and cracks on the surface of the product are found. The weld is smooth and uniform, the transition between the weld bead and the base metal is smooth, welding slag and spatter Clean up.

During the epidemic, Dalian Guangtong Steel Structure Co., Ltd. accelerated the recovery of production and expanded production capacity while ensuring the safety of employees. This is in line with the company's own professional steel structure design team; stable and skilled first-line production technical workers; large-scale steel structure production equipment , Production, packaging, transportation, loading and unloading services and a complete quality inspection system are inseparable. The workers are united and always fighting in their posts, making all-out efforts to produce steel structure products. The premise of ensuring product quality To ensure timely delivery.

Dalian Guangtong Steel Structure Co., Ltd. is a large modern steel structure enterprise with construction and design qualifications in Liaoning Province. The company covers an area of 18,000 square meters, of which the workshop area is 13,000 square meters, with dozens of advanced processing and testing equipment. Our company's responsibility is to provide customers with high-quality services, to ensure product quality while strictly guaranteeing the delivery date and ensuring timely delivery. We take high-quality service as the core to meet customer needs and create more corporate achievements.