What are the connections of steel structures?

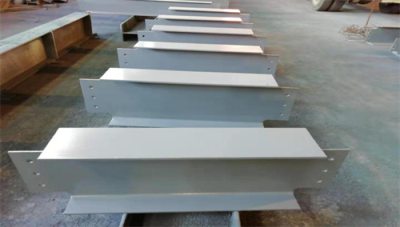

Steel structure connection refers to the mutual connection between steel structure members or components. Steel structure is a kind of structure composed of steel materials, which is one of the main types of building structure. The steel structure has the advantages of high material strength, steel toughness, good plasticity, uniform material and high structural reliability. The steel structure connection method applied by Dalian Fuxin Guangsheng Trading Co., Ltd. is as follows:

1. Weld connection

The welding connection in steel structure mainly adopts electric arc welding (that is to say, at the connection of components, the welding rod or welding wire placed at the welding position is melted by the high temperature generated by the electric arc, so that the components are connected together). Arc welding is divided into manual welding, automatic welding and semi-automatic welding. Automatic welding and semi-automatic welding, can use submerged arc welding or gas (such as carbon dioxide gas) protection welding.

The advantages of weld connection are strong adaptability to geometry, no weakening of cross section, automatic operation, good tightness of connection, large structural rigidity, etc.

2. Ordinary bolt connection

The common bolted connections include bolt bars, nuts and washers. The common bolt is made of common carbon structural steel or low alloy structural steel, which is divided into two types: crude bolt and refined bolt. The rough bolt is made of unprocessed round bar, the hole diameter of bolt is 1.0-1.5mm larger than that of bolt bar, which is convenient for loading and unloading and installation. It is suitable for the connection of secondary components or temporary fixation on site, or for the connection of transferring tension by bolt. The refined bolt is made of bar steel by cutting on lathe. The diameter of the bar is 0.3-0.5mm smaller than the hole diameter. Its shear performance is better than that of the crude bolt.

Ordinary bolt connection has the advantages of convenient loading and unloading, convenient installation, etc.

3. High strength bolt connection

High strength bolt connection also consists of bolt rod, nut and washer. It is made of steel with high strength by overheating treatment. The high-strength bolt connection shall be tightened with a special wrench, and the prescribed pre tension shall be applied to it. High strength bolt shear connection can be divided into two types: friction type and shear compression type (or pressure bearing type).

The high-strength bolt connection has the advantages of small friction shear deformation and good elasticity, which is especially suitable for the structure with dynamic load. The bearing capacity of bearing type is higher than that of friction type, and the connection is compact.

4. Rivet connection

Rivets are made of rivet steel with good upsetting performance. The construction procedure of rivet connection is to first make a hole 1.0-1.5mm larger than the nail diameter on the connected component. Then the rivet with a semicircular head at one end is heated to a cherry red color, inserted into the hole, and then riveted with a rivet gun or rivet machine to fill the rivet hole and make another rivet head. After riveting, the rivets are cooled and contracted to produce clamping force on the connected plate bundle, which is conducive to force transmission. The toughness and plasticity of rivet connection are good, and it is suitable for long-span steel structure with large dynamic load.

Rivet connection has the advantages of reliable force transmission, good toughness and plasticity, easy quality inspection and good dynamic load resistance.

Dalian Fuxin Guangsheng Trading Co., Ltd. adheres to the concept of "integrity and pragmatism, innovation and win-win, satisfactory service, and the most outstanding". Based on the brand-new management mode, perfect technical business, considerate service and excellent quality, it constantly provides high-quality service, continuously improves management, adheres to the principle of customer first, and strives to provide customers with satisfactory products and considerate service, and pursues customer-oriented service We will strive to build an enterprise with sustainable development and excellence.